Advanced visualization systems include three main components: display, graphics, and software. Integrating those components into an organization’s facility is one of the key steps in the design and installation process. But, organizations aren’t cookie cutter. Performance needs, available space, and budget all vary from one to the next.

That’s where AV fabrication comes in. Working with an experienced integrator can help your organization achieve its goals for an advanced visualization system within the constraints of your facility and your budget. That could mean writing custom code to provide functionality that’s not commercially available or developing custom workstations to create the best possible environment for viewing three-dimensional data in real time.

However, the main area where integrators use fabrication is in the display system. Whether the display is projector-based, a direct-view LED, or a matrix of LCDs, the integrator takes into account performance requirements and, most importantly, the type of facility where the display will be installed.

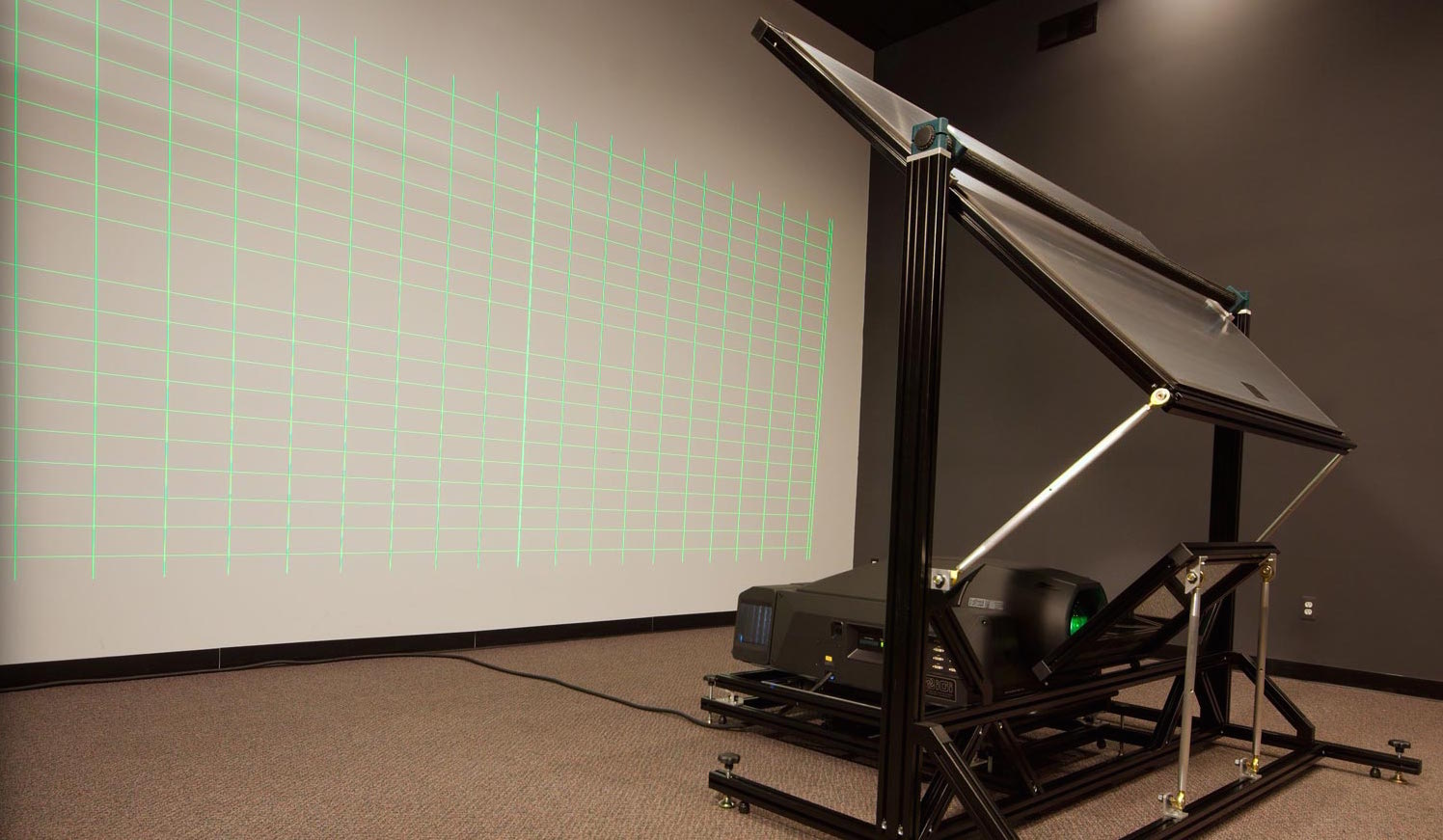

In many cases, the limitations and challenges of a particular facility necessitate fabrication. When designing a rear-projection system, for example, the integrator should consider desired image dimensions, throw distance (distance from the lens to the screen), and how much space an organization can provide behind the screen for optics and installation.

These considerations present a challenge because space is often an organization’s most valuable commodity. To meet the demands, integrators need to look at the space available and devise a solution that minimizes the amount of area required behind the screen.

AV integrators use space reduction techniques like folding mirrors and projection stands. For example, with this custom fabrication in place, integrators can reduce the capacity required behind a screen to 10 feet from 20 feet, saving 250 square feet of space within the room.

An advanced visualization system’s rear-projection screen might be made of fabric, acrylic or glass. Integrators must consider the system’s screen type and fabricate any necessary safety and performance enhancements.

In the case of acrylic or glass screens, that might mean designing a structure underneath the screen to absorb building movement and lower the risk of the screen cracking. For fabric screens, the integrator may need to design a structure to allow for tensioning and reduction of screen movement.

It’s important to work with your advanced visualization integrator and communicate any specific space requirements or limitations so that the design team can customize a solution to fit your needs. Testing, quality assurance, and design changes should all be integral parts of the integration process.

At IGI, we custom fabricate all of our mechanical structures and fit them with fabric panels and projection screens in our own shop. This AV fabrication process ensures material quality and structural integrity based on design specifications. Our knowledge and flexibility allows us to respond faster to design changes and meet important deadlines.

Contact us to learn more about how IGI can design a an advanced visualization system to help your organization exceed its goals.