Think back a few decades and you will probably remember the fanfare surrounding the launch of a new vehicle from a car company. Might be 2, 4 or even 6 years between new model releases. Much of this was because of the design and engineering process and getting the results wanted before getting into the tooling and manufacturing process.

Engineering was still mostly paper back then. Design was too, but then the clay modeling process would start and it would take months to take the design from paper and turn it into a physical model that could be reviewed by both engineering and design teams. Typically, engineering would realize something was not quite right with one aspect or another, and design would not like what they were seeing when it was in full scale and sitting in front of them.

That would mean, "back to the drawing board", literally. Unfortunately, the time in and out of this clay model process could be as much as 18 months, and it may happen more than once or twice. This was primarily the reason new car models took so long to get released.

Advanced visualization technology changed this significantly. Just like diagnostic imaging significantly reduced exploratory surgery, the ability to engineer and design digitally allowed for many things to happen. Design and engineering reviews could now take place with virtual renderings of models that allowed for the elimination of most mistakes prior to starting on the clay modeling process. Advanced visualization has even improved the crash testing process and some virtually rendered crash tests are able to replace some of the initial crash testing that can cost millions of dollars.

So, why are some car companies using clay still? Maybe the existence of a $28m Rolls Royce answers that. It could also be that engineers and designers that have used clay all of their lives are just more comfortable having it remain in the process. The video in this post goes into more detail. Thanks to advanced visualization, new model releases happen almost yearly now.

IGI was actually at the forefront of the digital and virtual revolution that took place in automotive design and engineering. Almost 25 years ago, IGI President Pat Hernandez created the first IGI PowerWall allowing engineers and designers an opportunity to see their car and truck models in full (1:1) scale on a projected screen in photorealistic resolution. This afforded them to make almost instant changes to engineering and design aspects to be reviewed in real time.

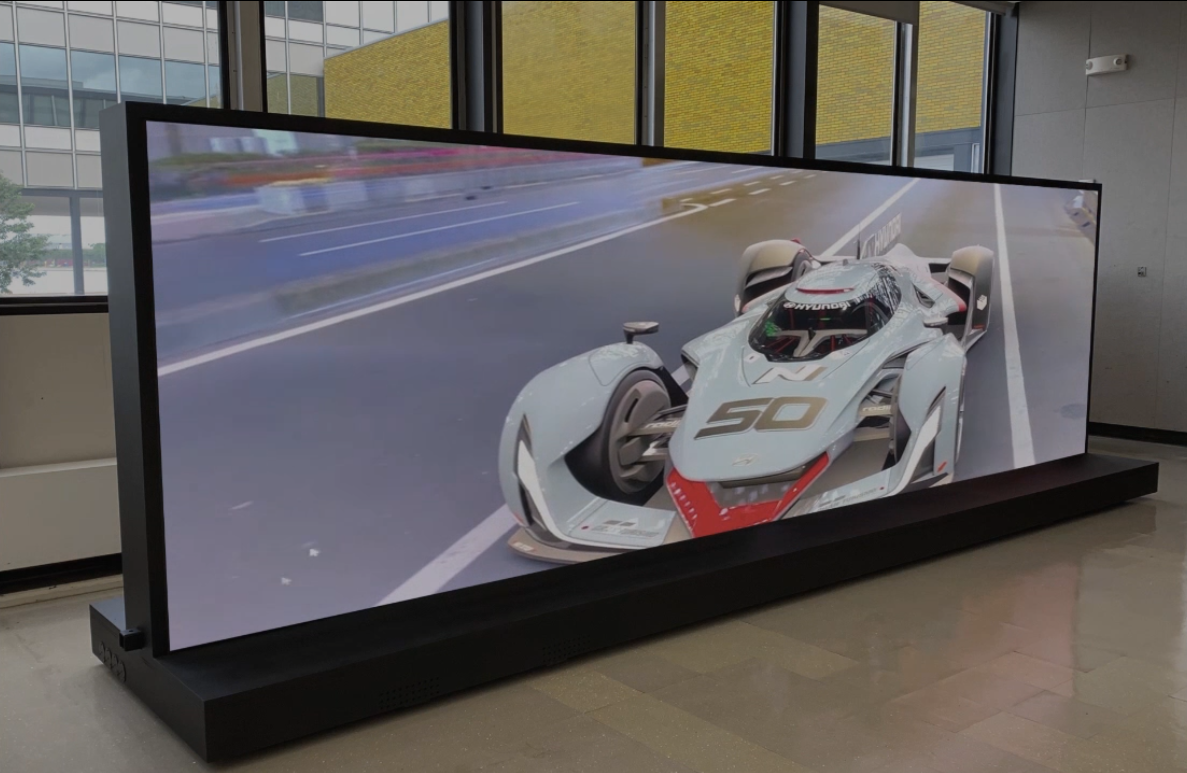

Today, IGI continues to help improve the workflow of engineering and design teams, with the introduction of the portable IGI DesignView that eliminates the need to print large images on rolling boards, and have them displayed in full scale at extremely high resolution (HD, UHD, 4K, etc.) and to position these DesignView systems wherever they are needed (design studio, next to the clay model).

Immersion Graphics, Inc. (IGI) provides audio visual design, engineering, consulting, product sales, control system programming, custom fabrication, installation, preventative maintenance, and extended support services out of its headquarters location in Detroit and west coast operation in Los Angeles. Additional offices are located in Indianapolis, and Grand Rapids.

Founded in 1998, IGI has installed numerous large-scale, ultra-high resolution systems throughout the U.S. in the automotive, higher education, medical, financial, and energy transmission markets, and for the United States military and other government agencies. Applications include industrial design, engineering and data visualization, mission-critical command & control room environments, presentation systems, video conferencing, digital signage, and a variety of commercial AV solutions for emerging markets where the simultaneous visualization of 3D models and complex data by a group is essential to effective decision making. To get an in depth look at what we do, see our website at www.werigi.com, we are IGI.

IGI is minority owned, veteran owned, and a small business and SBA 8(a) program graduate.